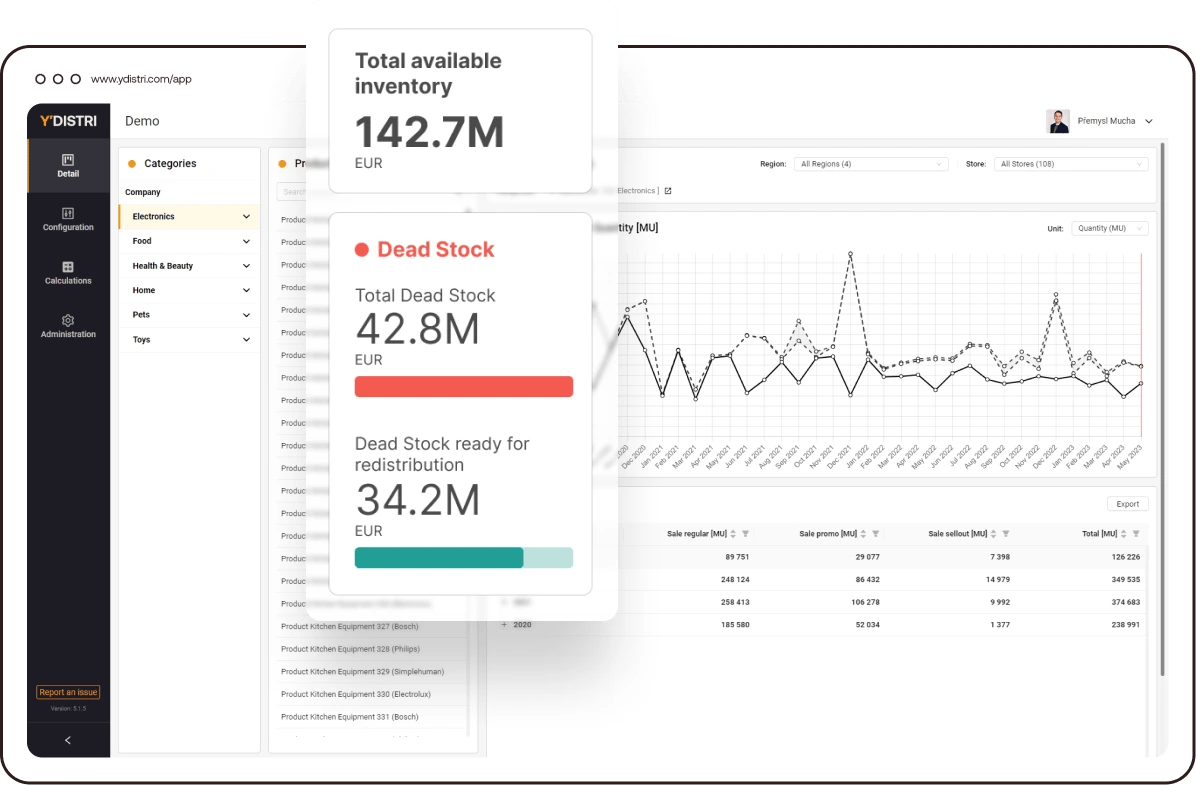

Y′platform is a cutting-edge SaaS solution tailored for optimizing sales and managing underperforming stock within retail chains.

App Features

Our intelligent algorithms automatically compute appropriate redistributions to new locations where the probability of selling is high.

Doing so, problematic inventory - underperforming retail stock turns into immediate cash without the need for discounting or even write-offs.

Our Approach

We tailor our solution to your specific business needs and can provide rapid implementation in couple of months. YDISTRI is a Microsoft Azure-based SaaS platform that can be seamlessly incorporated into any ERP system, avoiding tedious integrations.

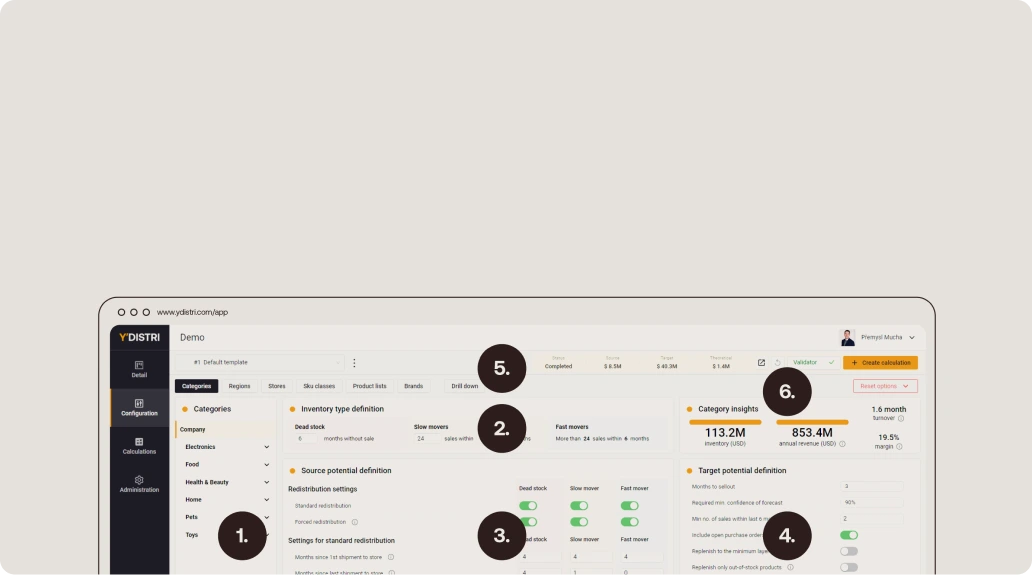

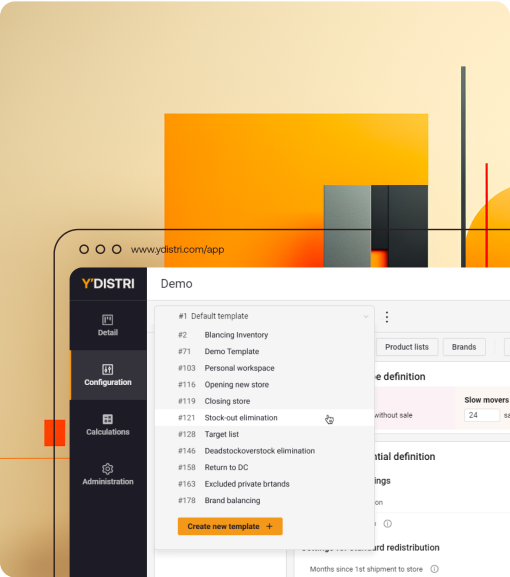

A few clicks to result

Quick & visual guidance from the initial settings to the desired results.

Safe testing simulations

Customers can model and configure various scenarios before settings redistribution parameters.

Simple visual workspaces

User-friendly interface provides a clear view of complex inventory structures and opportunities.

"By store-to-store transfers retailers can turn over dead stock more than 10x quicker than using traditional selling methods."

Martin Novotny

PetCenter

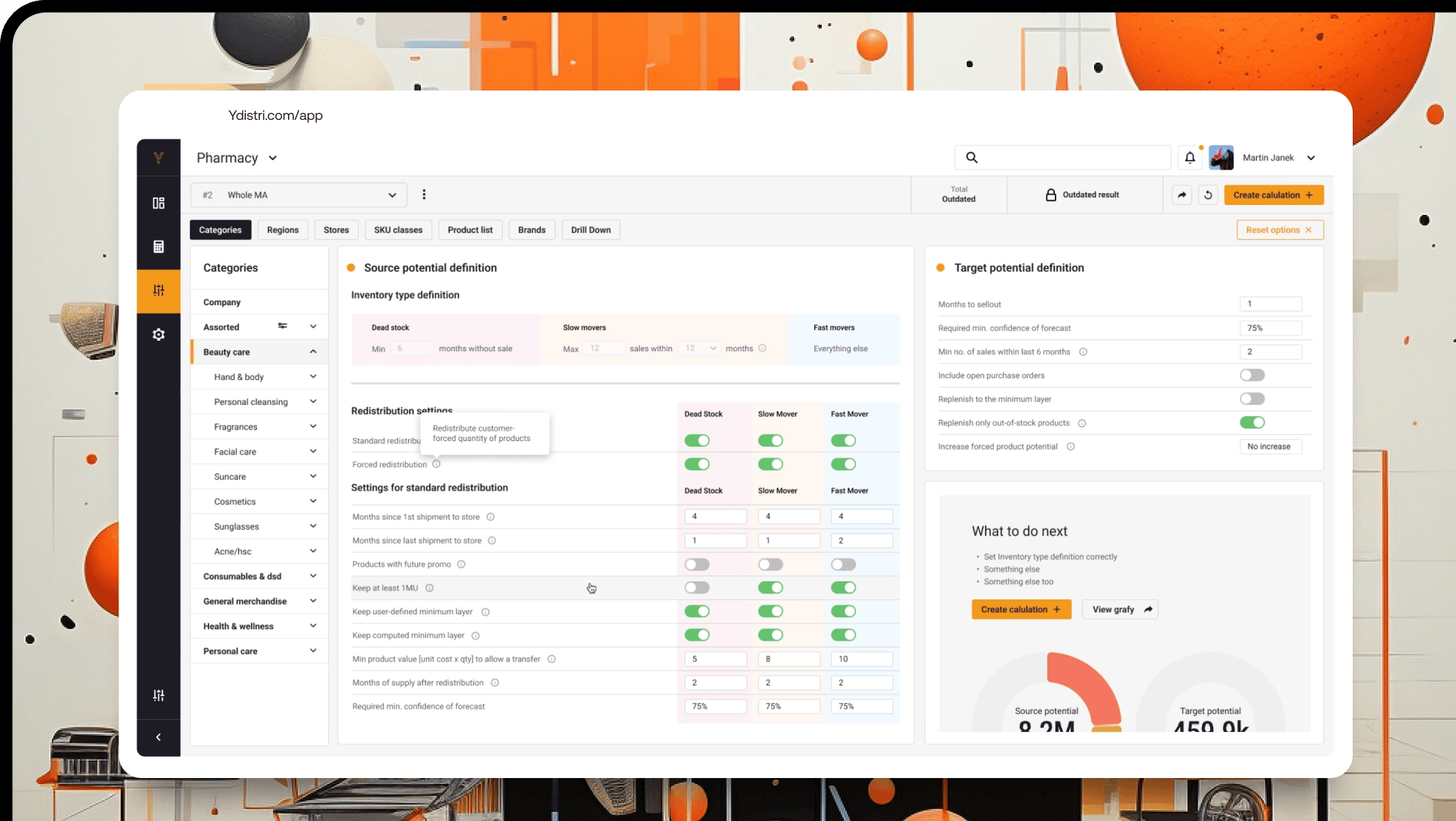

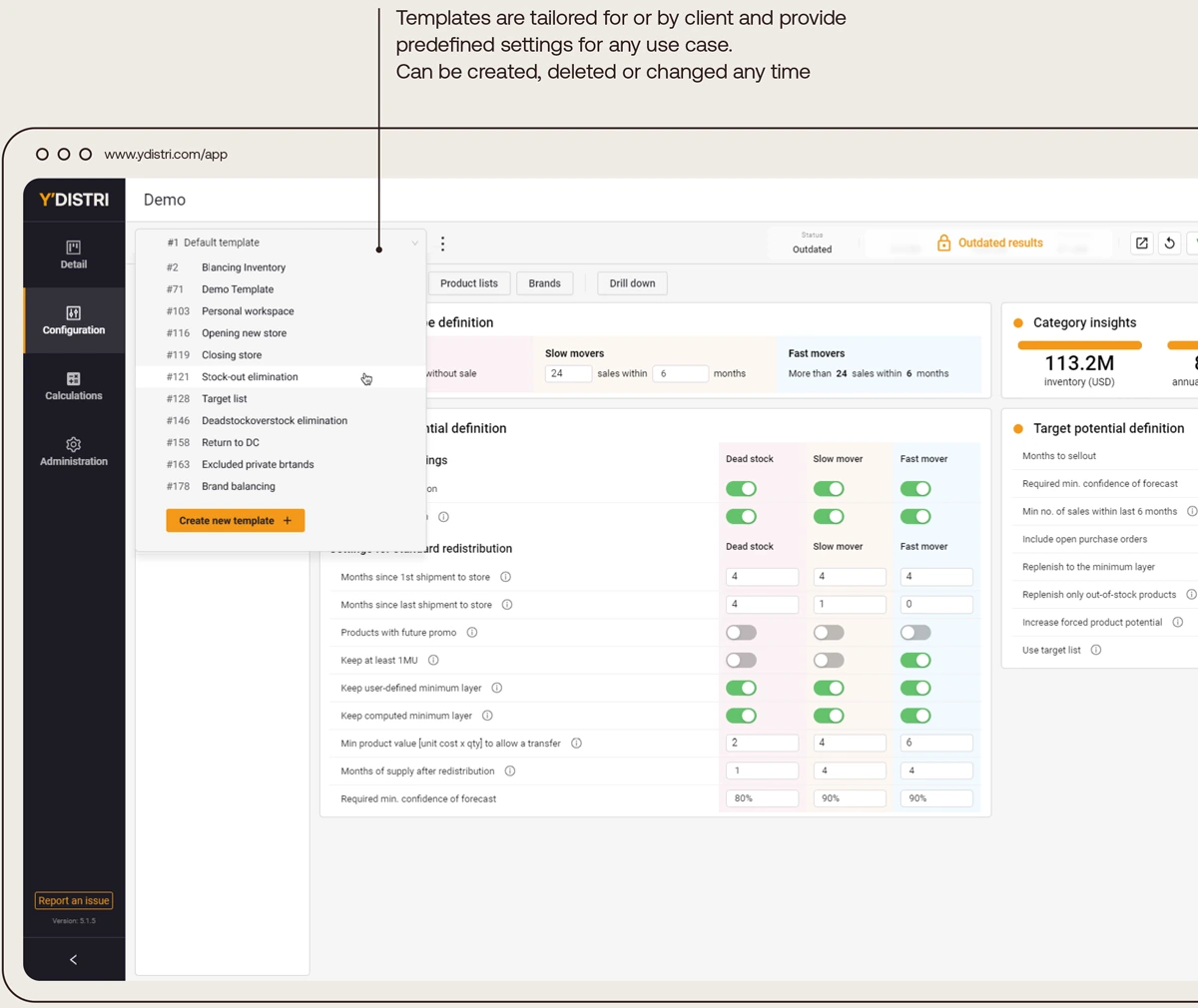

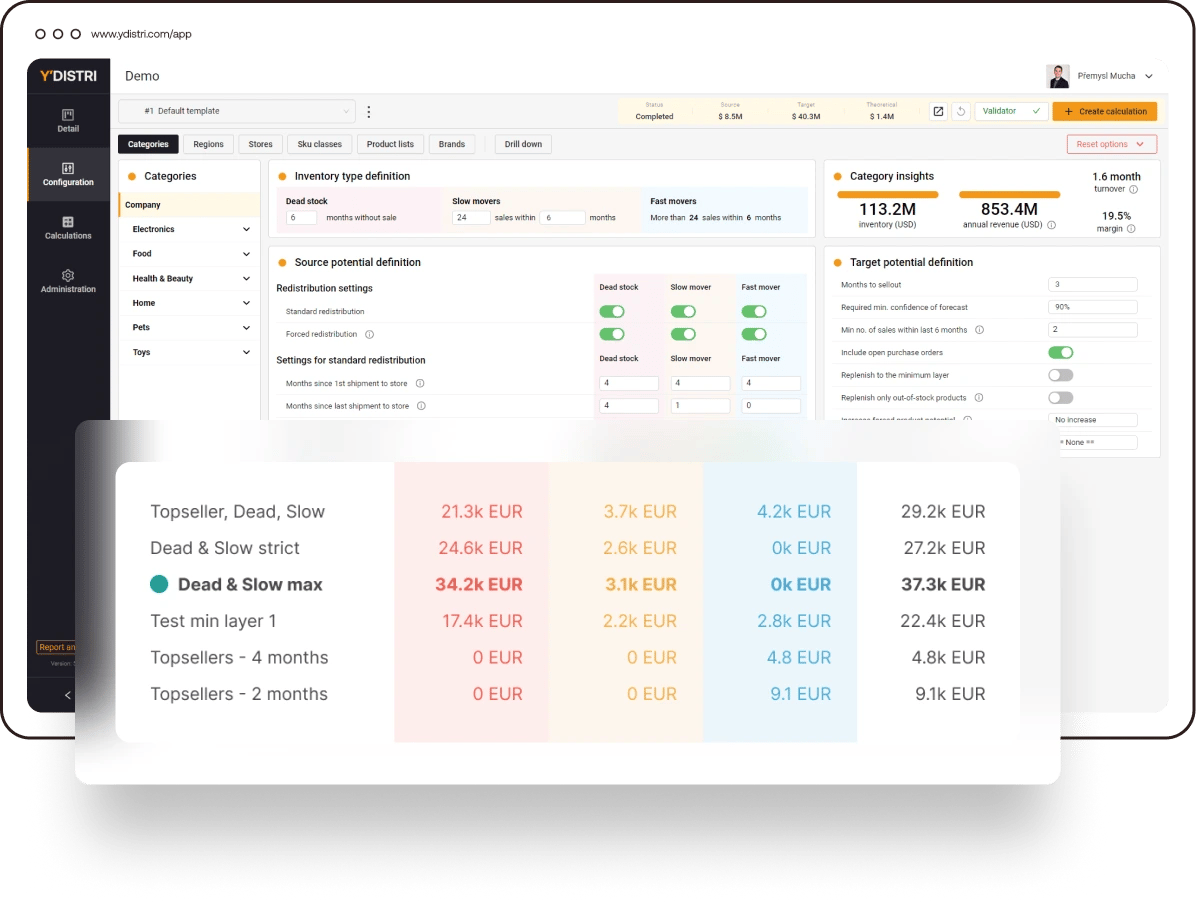

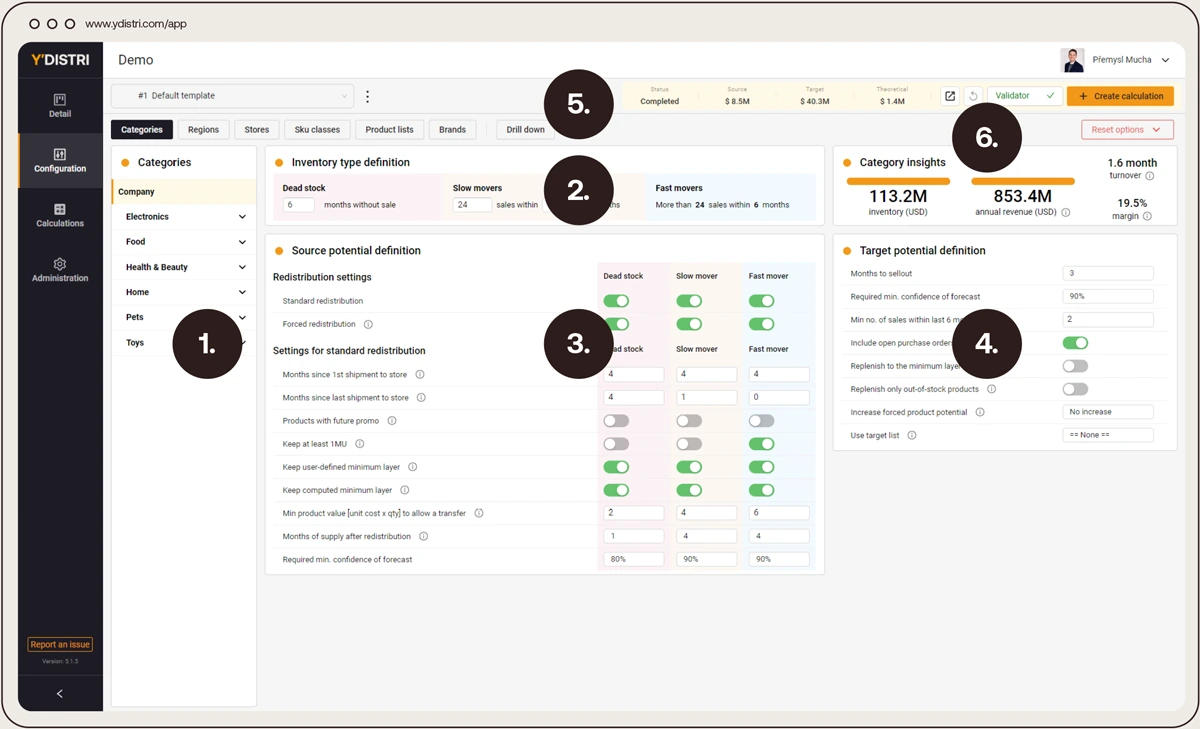

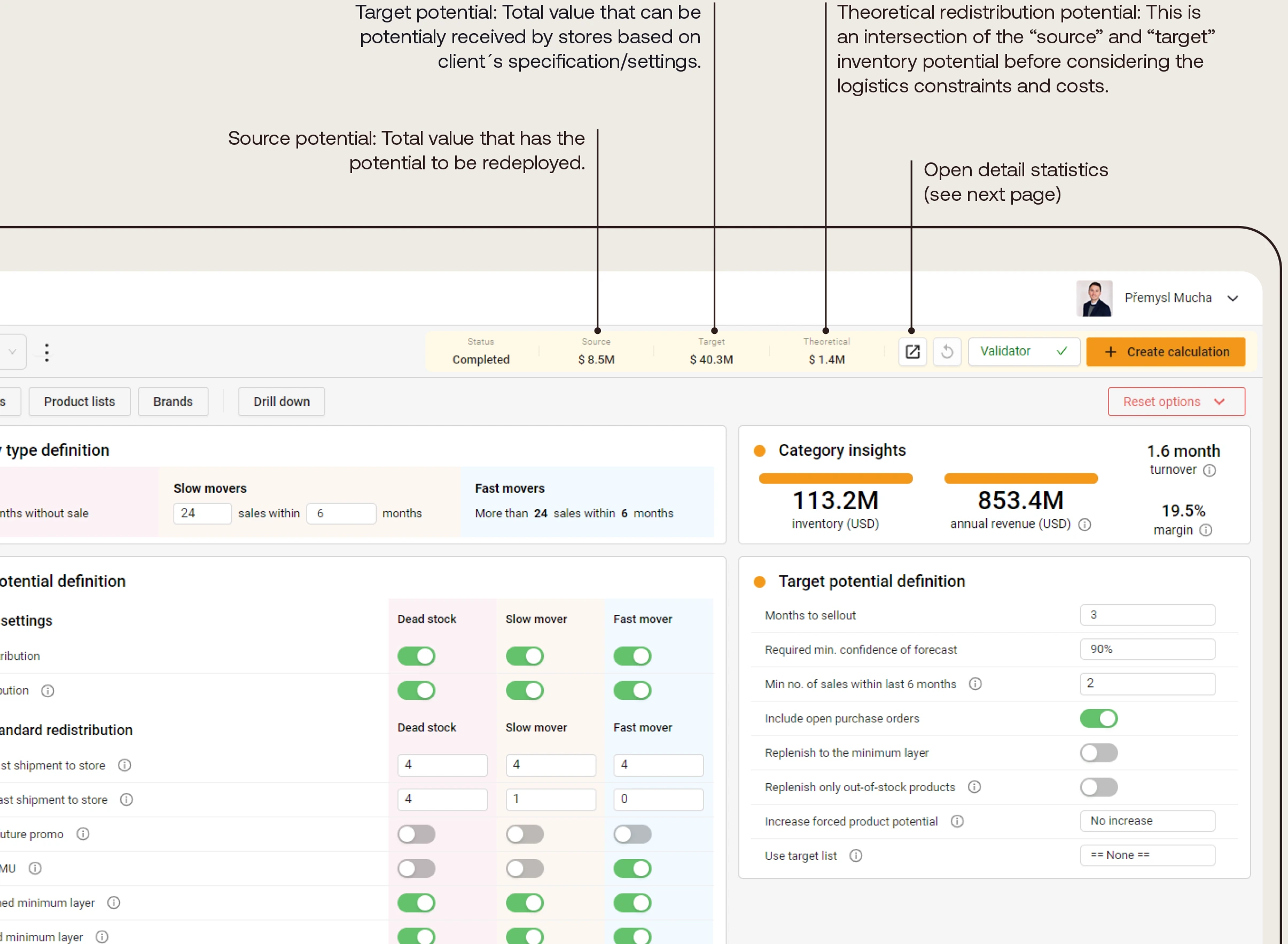

Y′02.

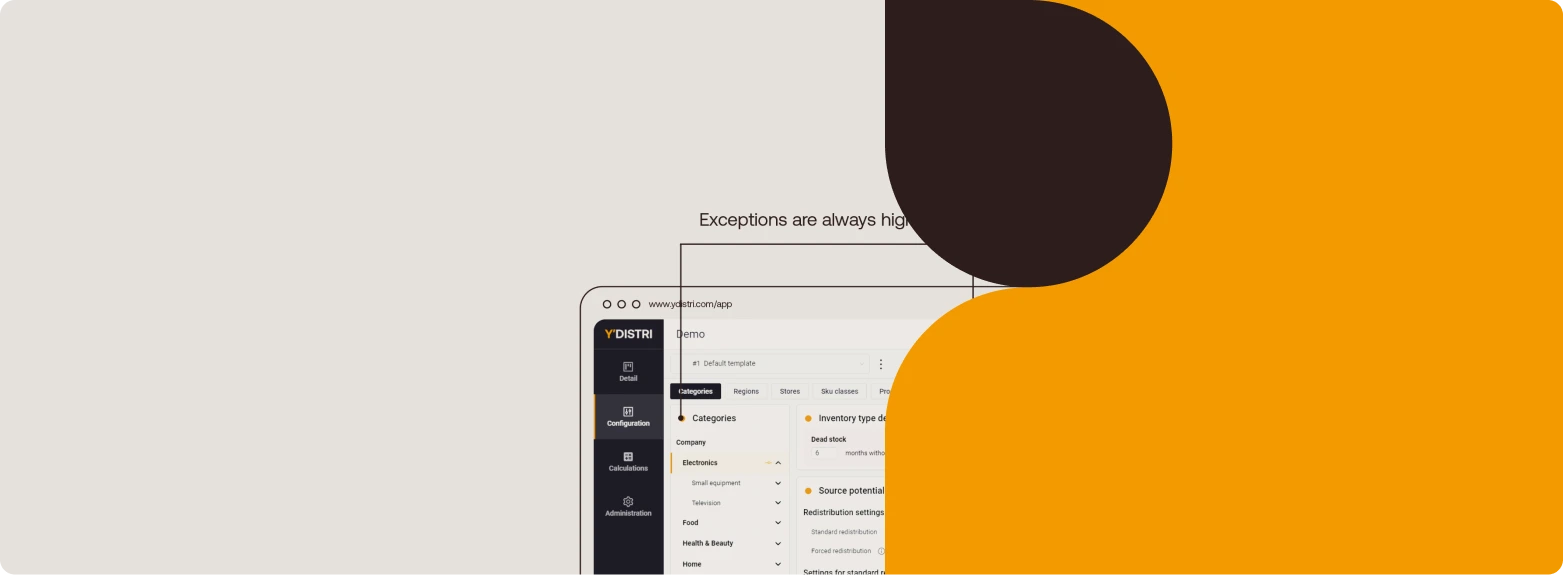

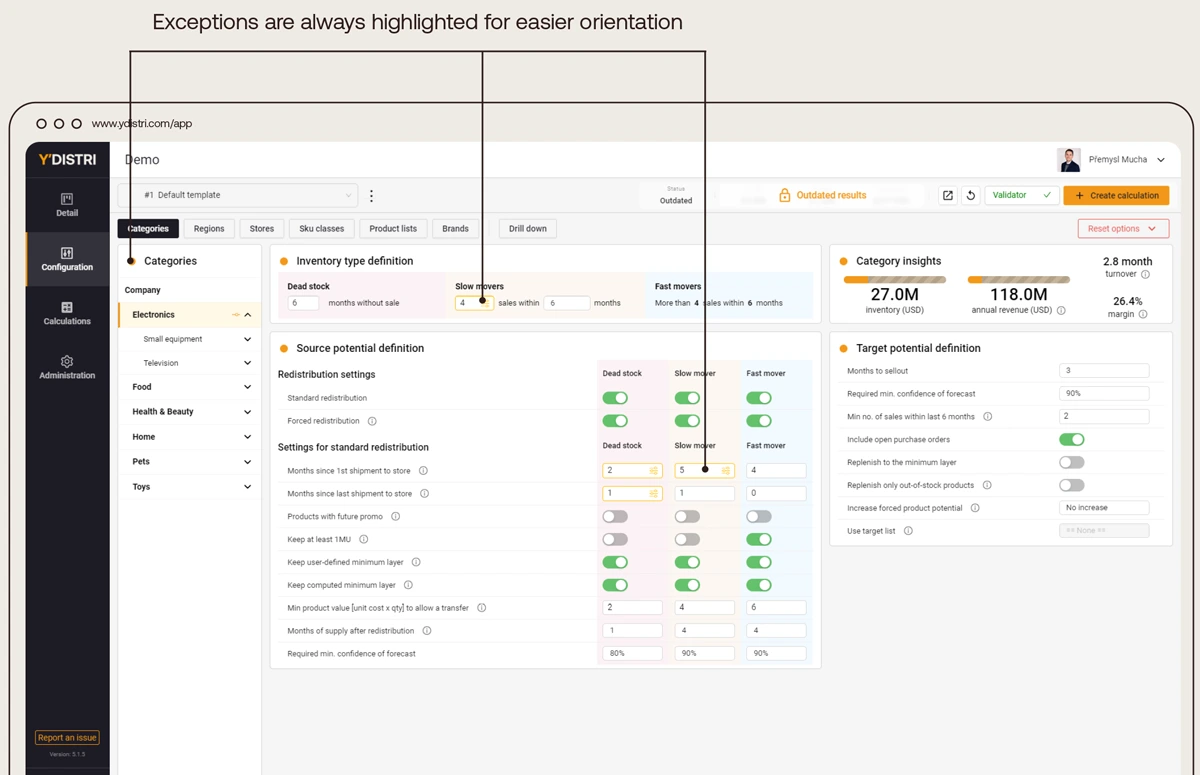

Main configuration screen

- Category tree.

- Inventory type definitions (Dead stock, Slow movers, Fast movers).

- Identification of inventory that can potentially be sent away.

- Settings to identify inventory that may be placed and sold in receiving stores.

- Results overview.

- Category insights.

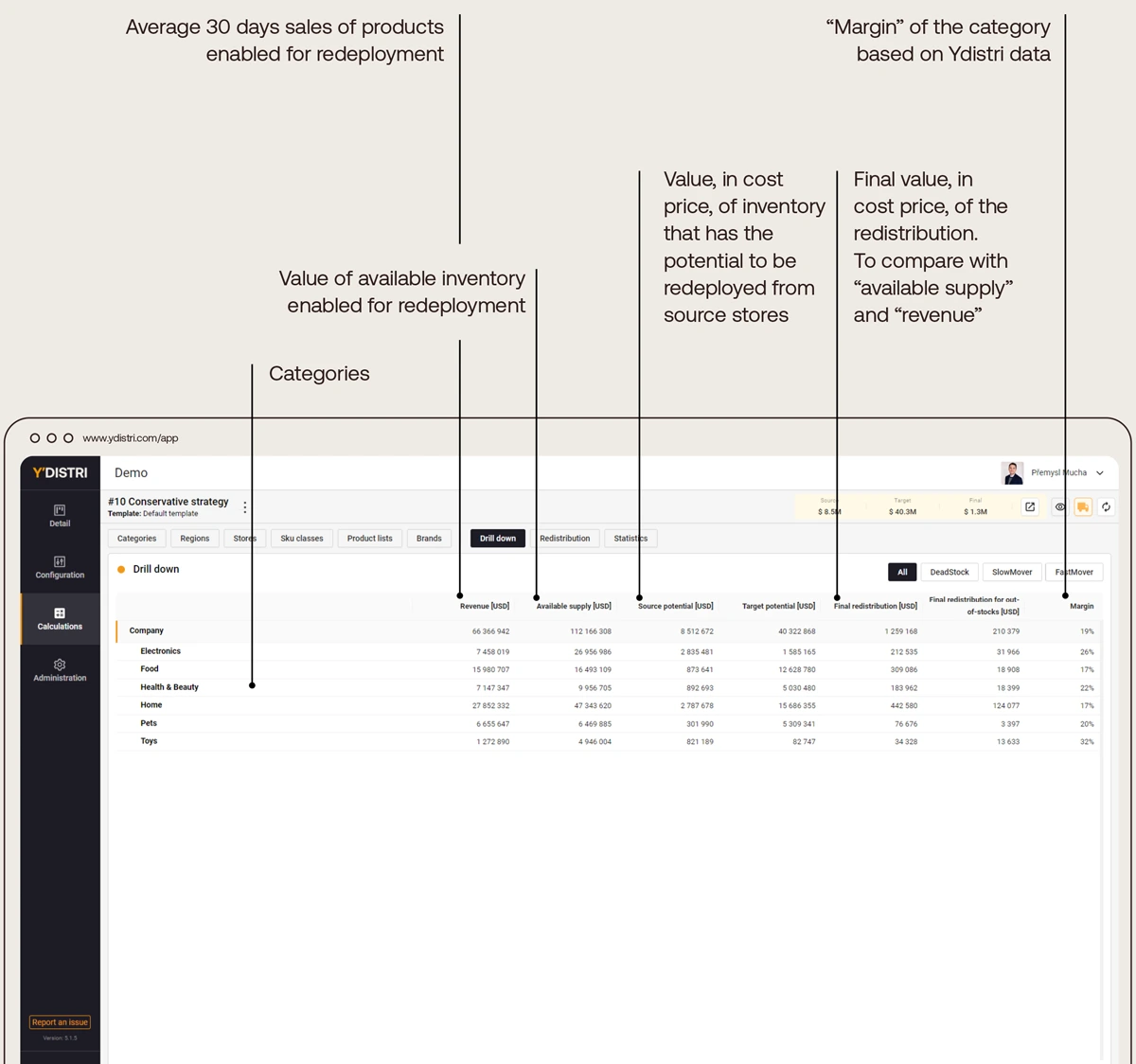

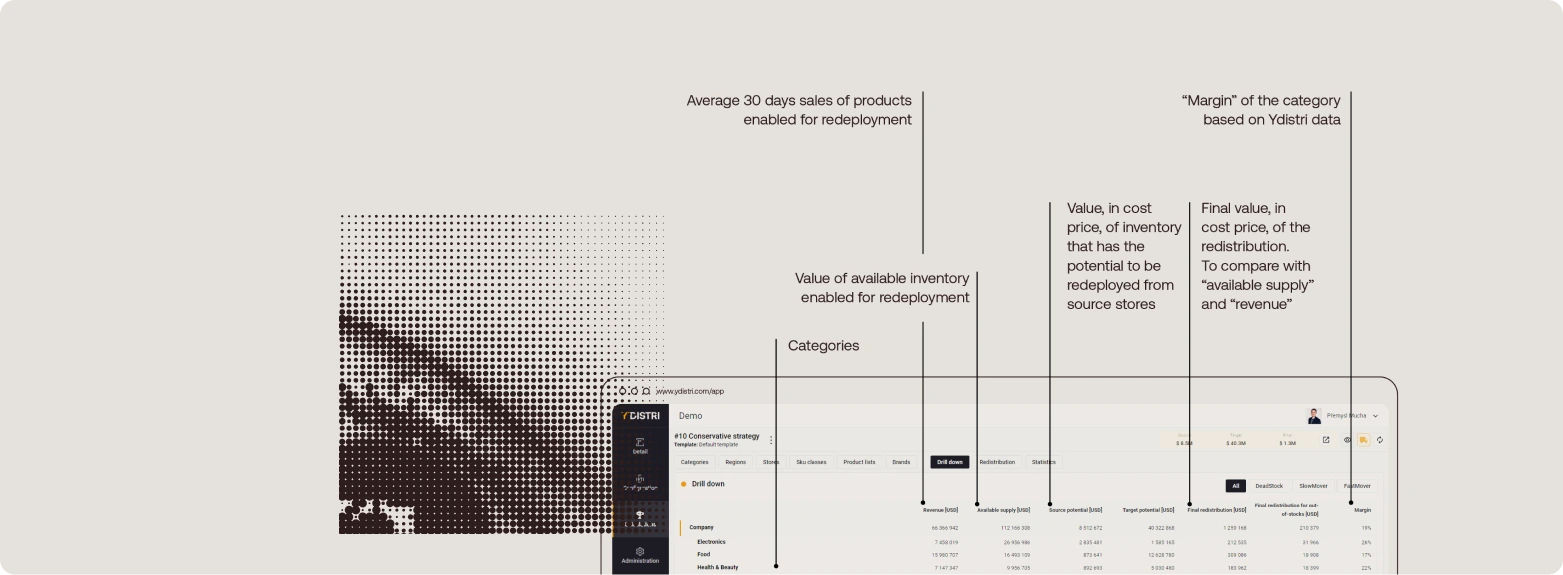

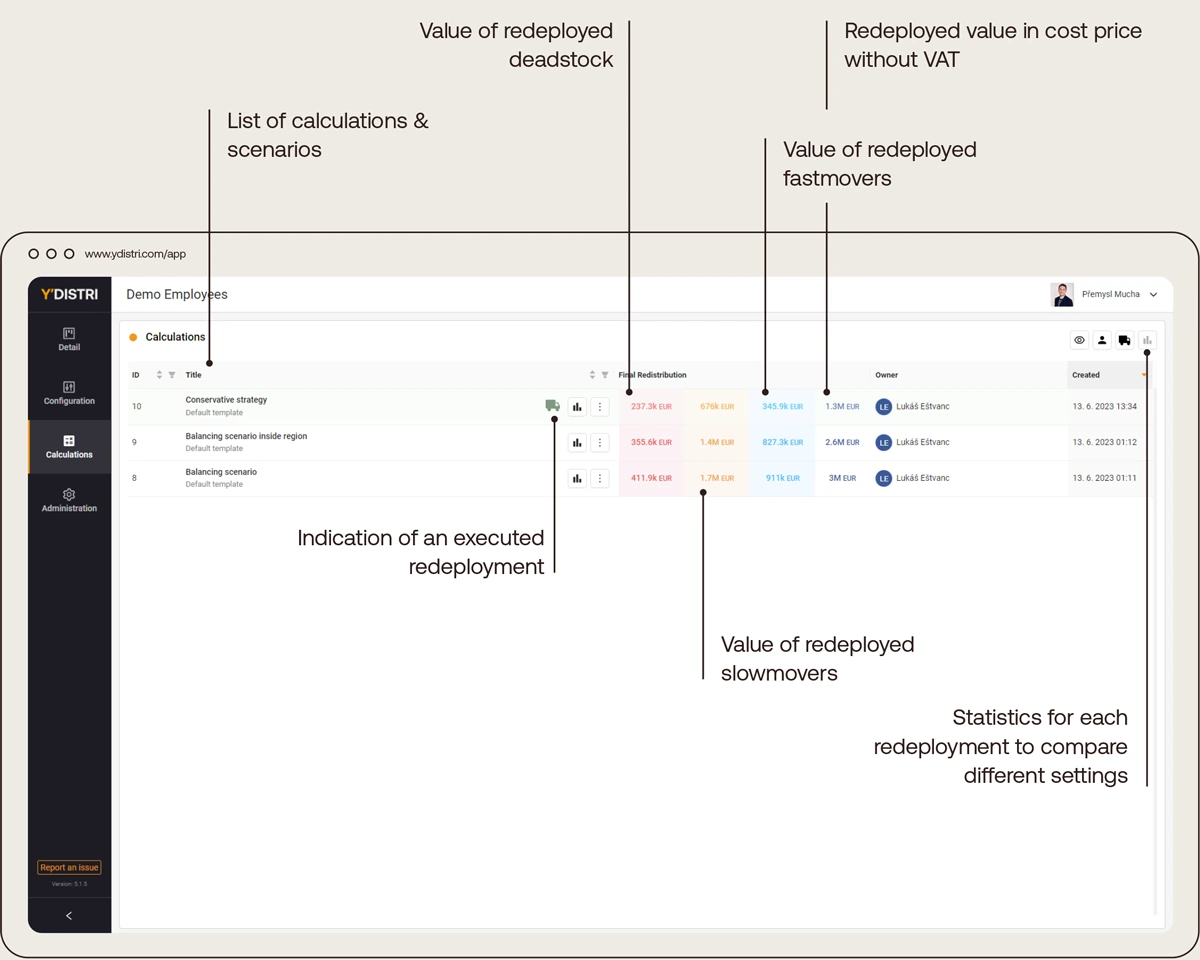

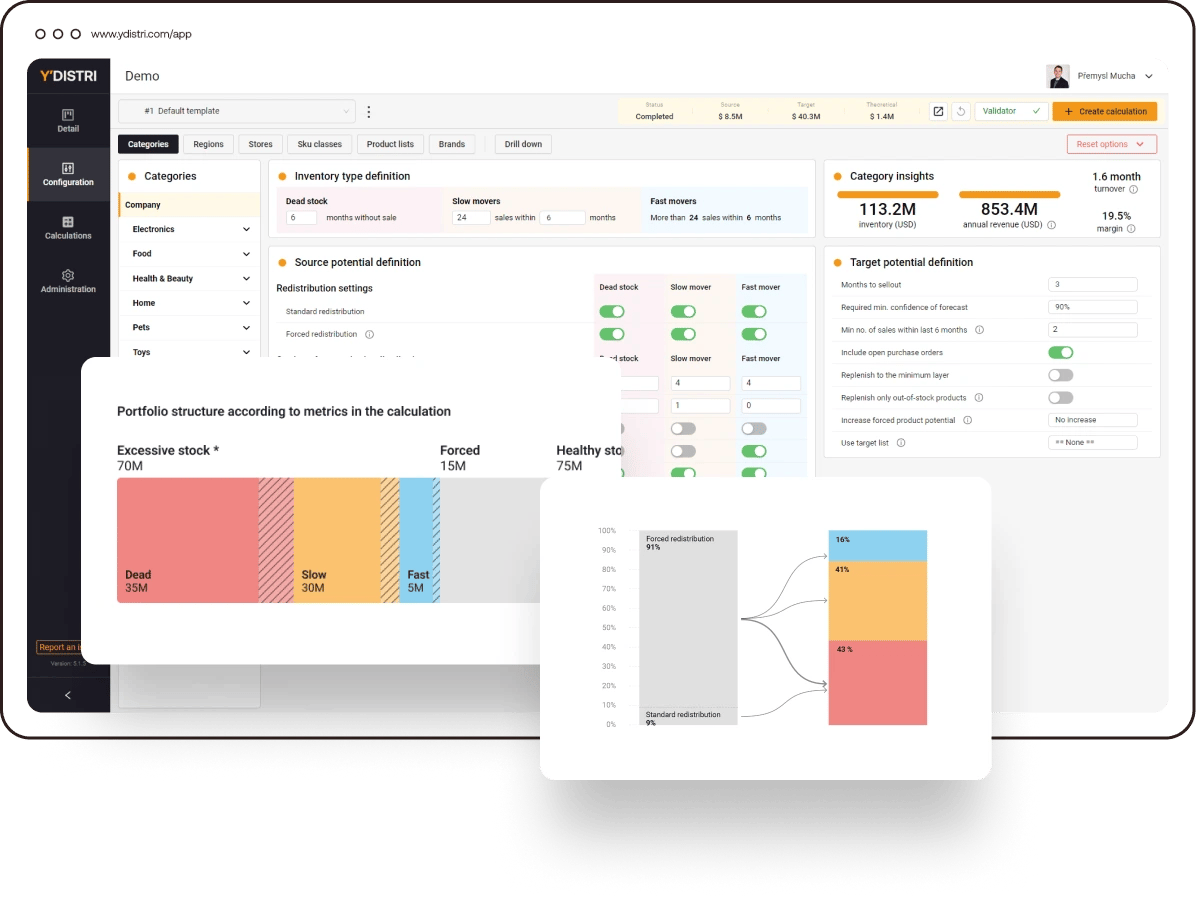

Y′03.

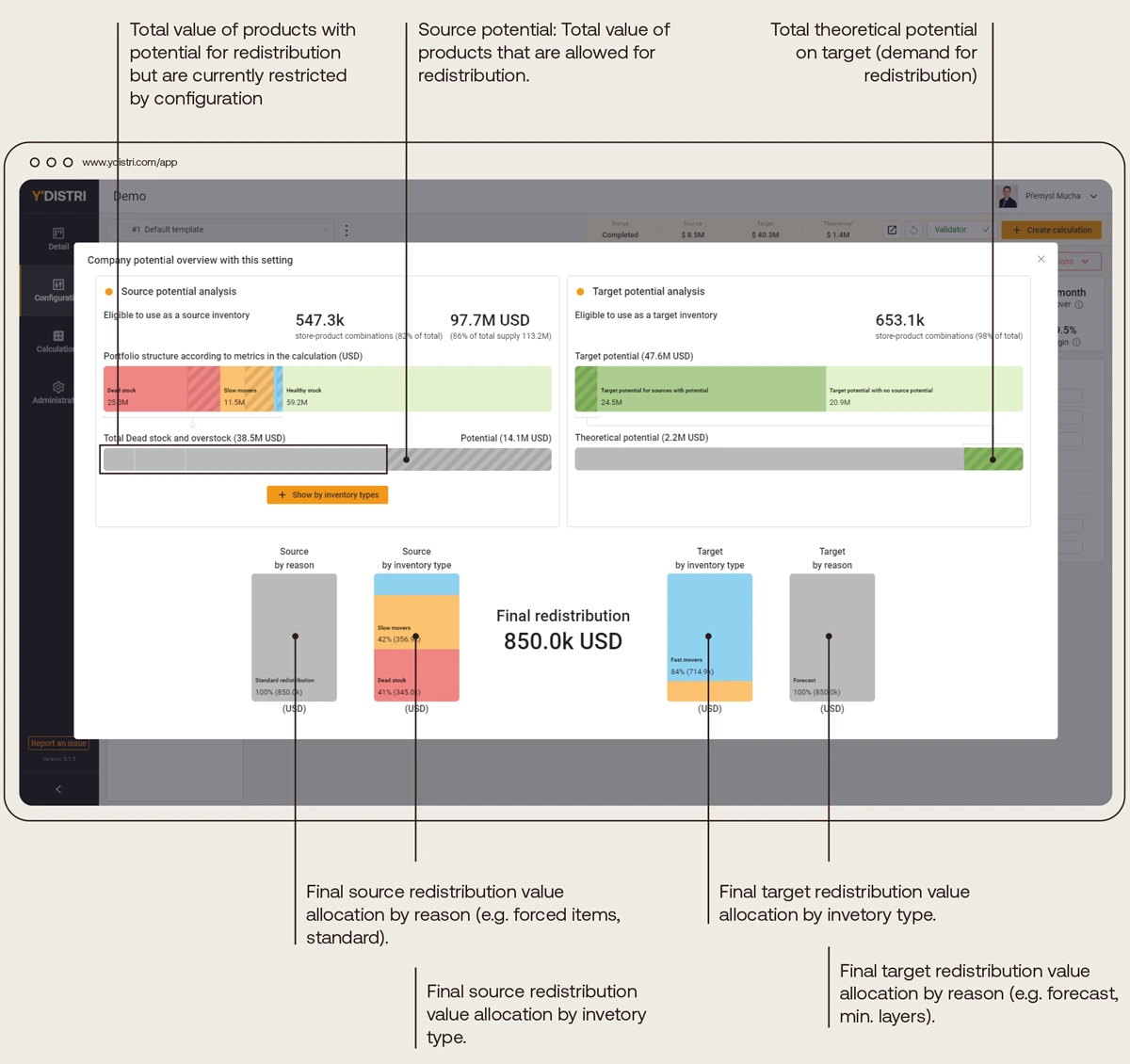

Dashboard of precalculated results

When the settings are changed these dashboards show the real impact of the current configuration. On-the-fly regime.

Statistics detail

Y′04.

Managing exceptions within categories

- The main configuration is done for all clients categories.

- Client can define exceptions for any category. Such as different definition of deadstock and its configuration for food.

- Special exceptions or exceptions on product level can be defined on the back-end level.

Y′05.

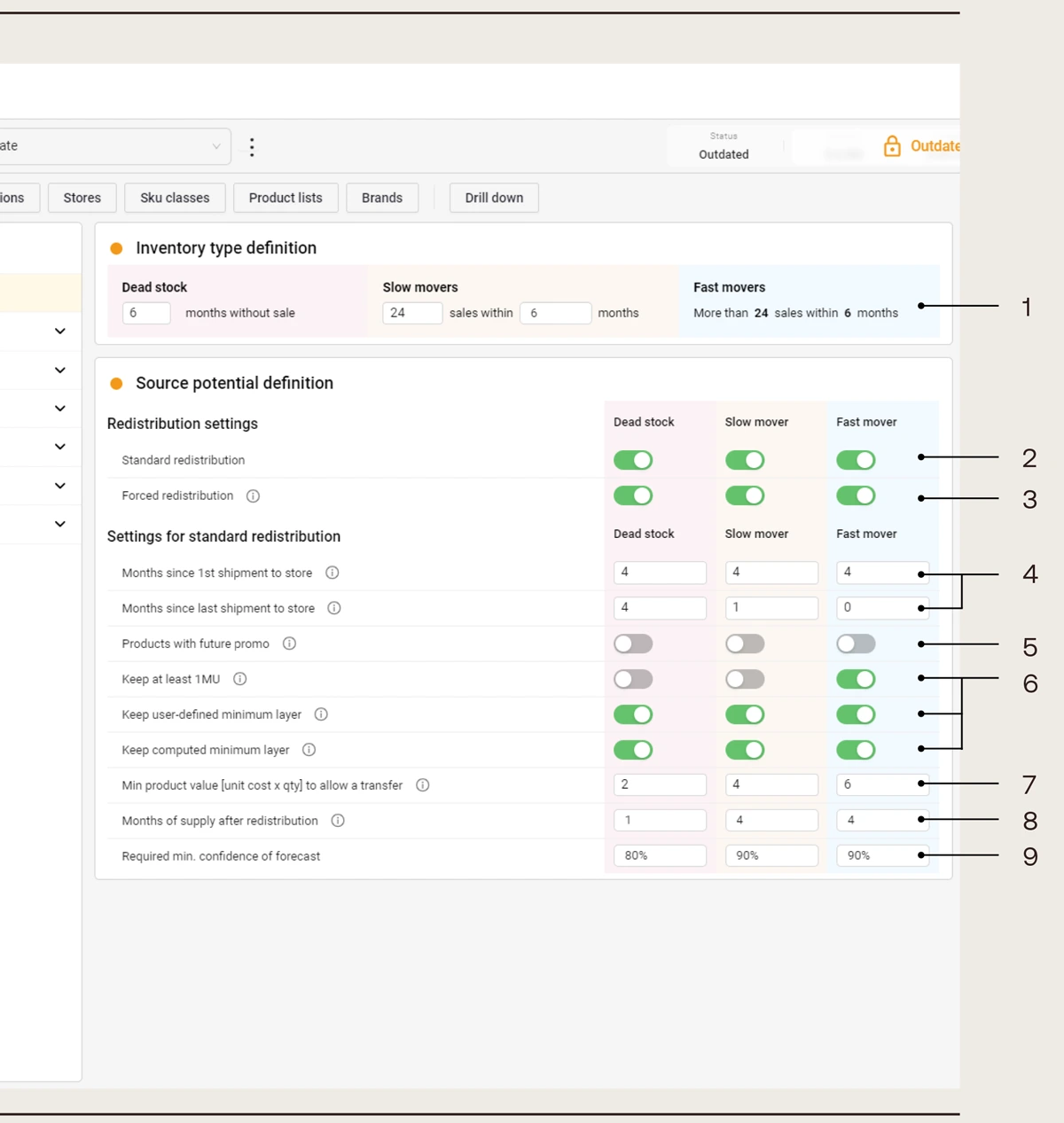

Simple but comprehensive settings

- Divide portfolio into 3 inventory types (dead stock, slow-movers, fast-movers).

- Enable selected inventory types for redeployment.

- Forced redistribution aims to depletethe inventory, that client identified as “not planogramed” or “unwanted” at store, to zero. No protection is applied.

- Setting protection on novelties and recently replenished inventory.

- Enabling products with planned promotion for redeployment.

- Protecting minimum layers (eg. minimum on shelves display, alignment with replenishment, etc.)

- Managing and controlling Picking & Packing costs (minimum values per picked line)

- Inventory definition that must be kept in store to ensure the demand is covered within the specified time period. The demand is based on Ydistri probabilistic forecast.

- The forecast confidence indicates the probability with which the inventory, we keep at store, will cover the demand defined above. The higher the confidence the more remains and the less is redeployed.

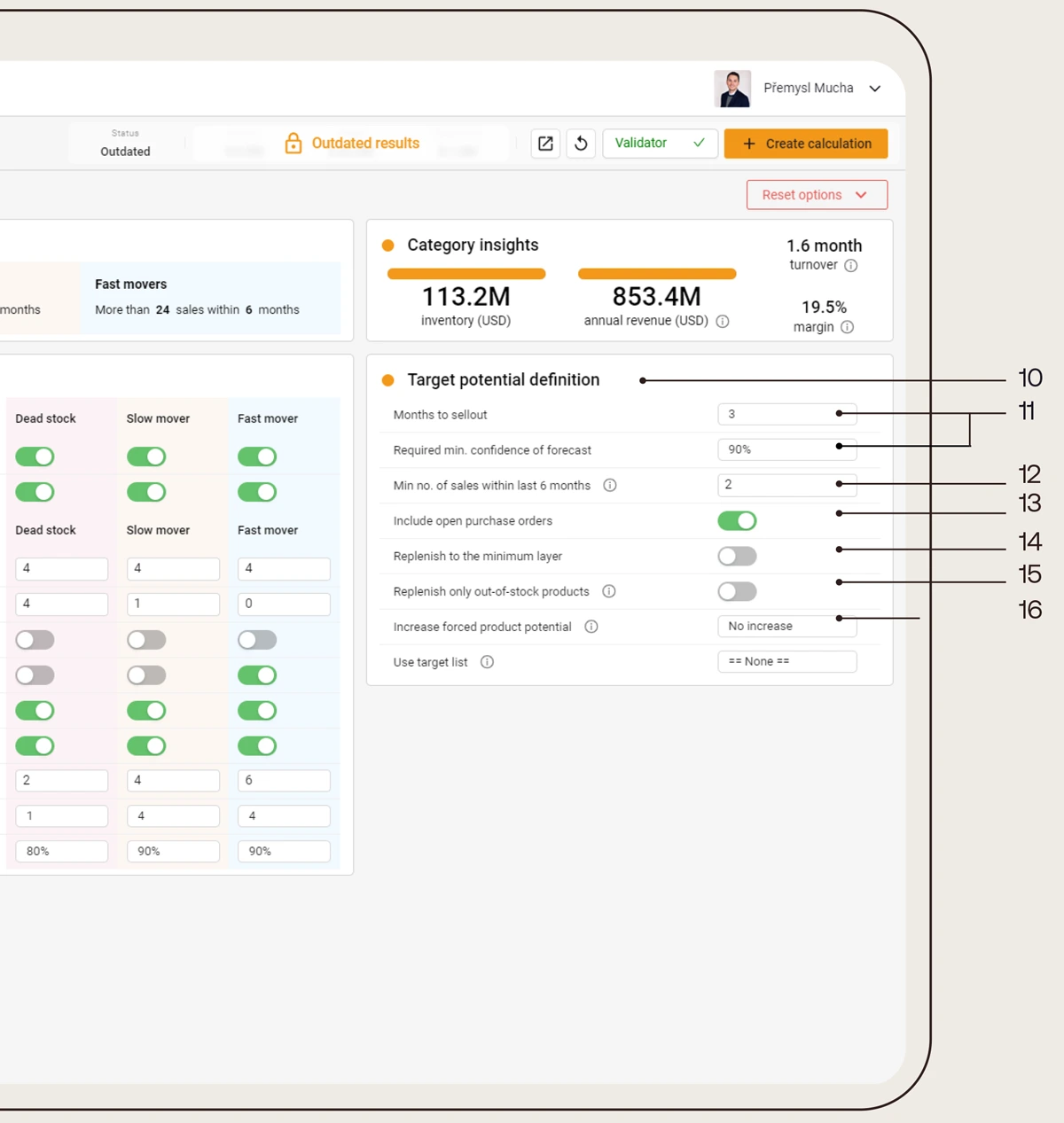

- Determining what is desired to be received at stores.

- Inventory quantity specification that canbe reached after redeployment. Inventoryis desired to be sold within the specified time period with defined probability. The higher confidence level, the smaller inventory quantity after redistribution.

- The location can receive the forecasted supply only if the product sales have the specified frequency.

- Include open purchase orders into available inventory of the receiving store.

- If enabled the redeployed quantity will always be replenished up to minimum layer (specified by client).

- Redeployed quantity is sent only to stores where the available inventory is zero.

- Specification of forced products redeployment size to receiving stores.

Y′07.

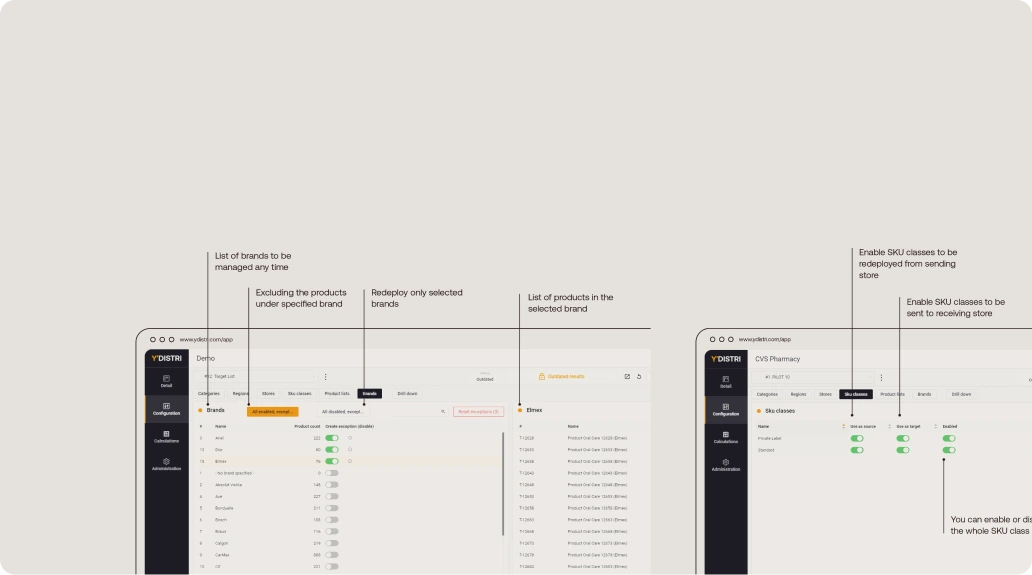

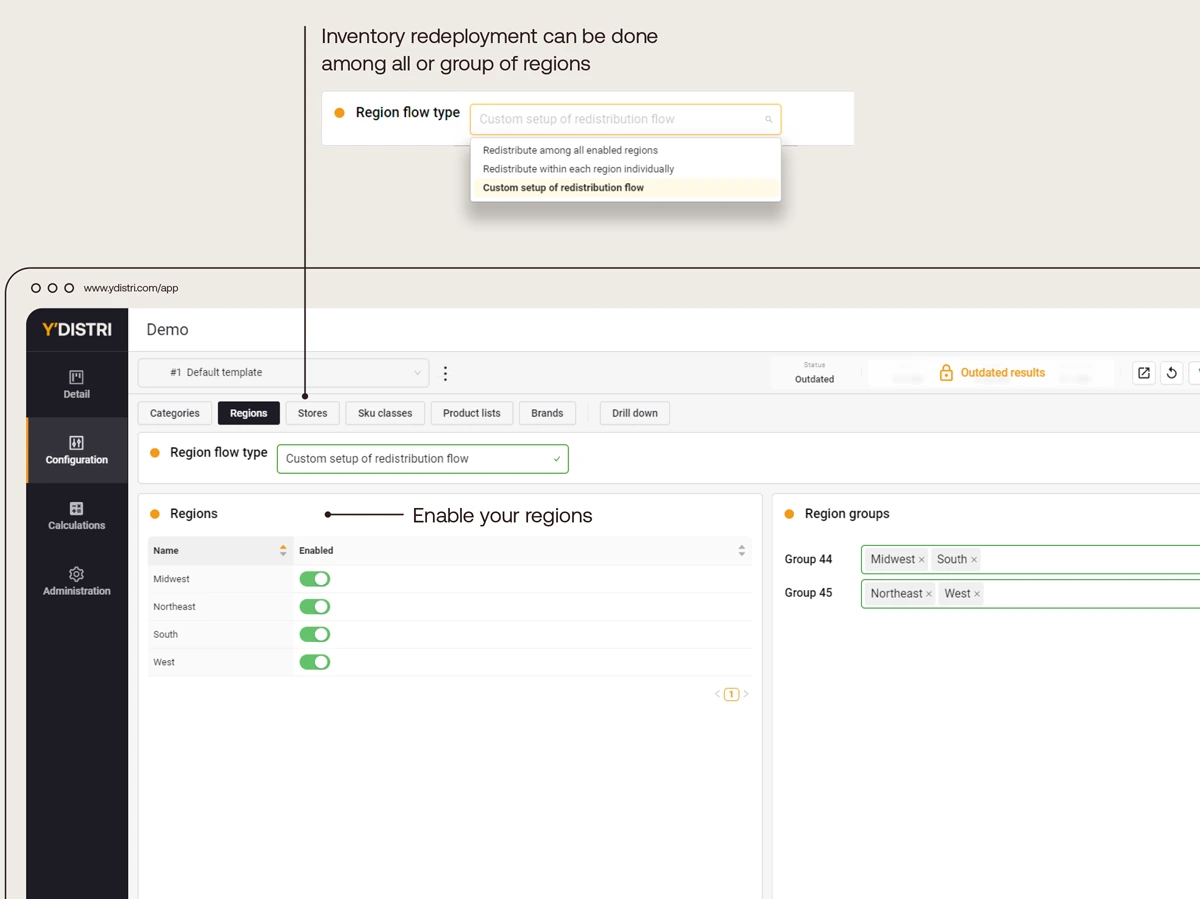

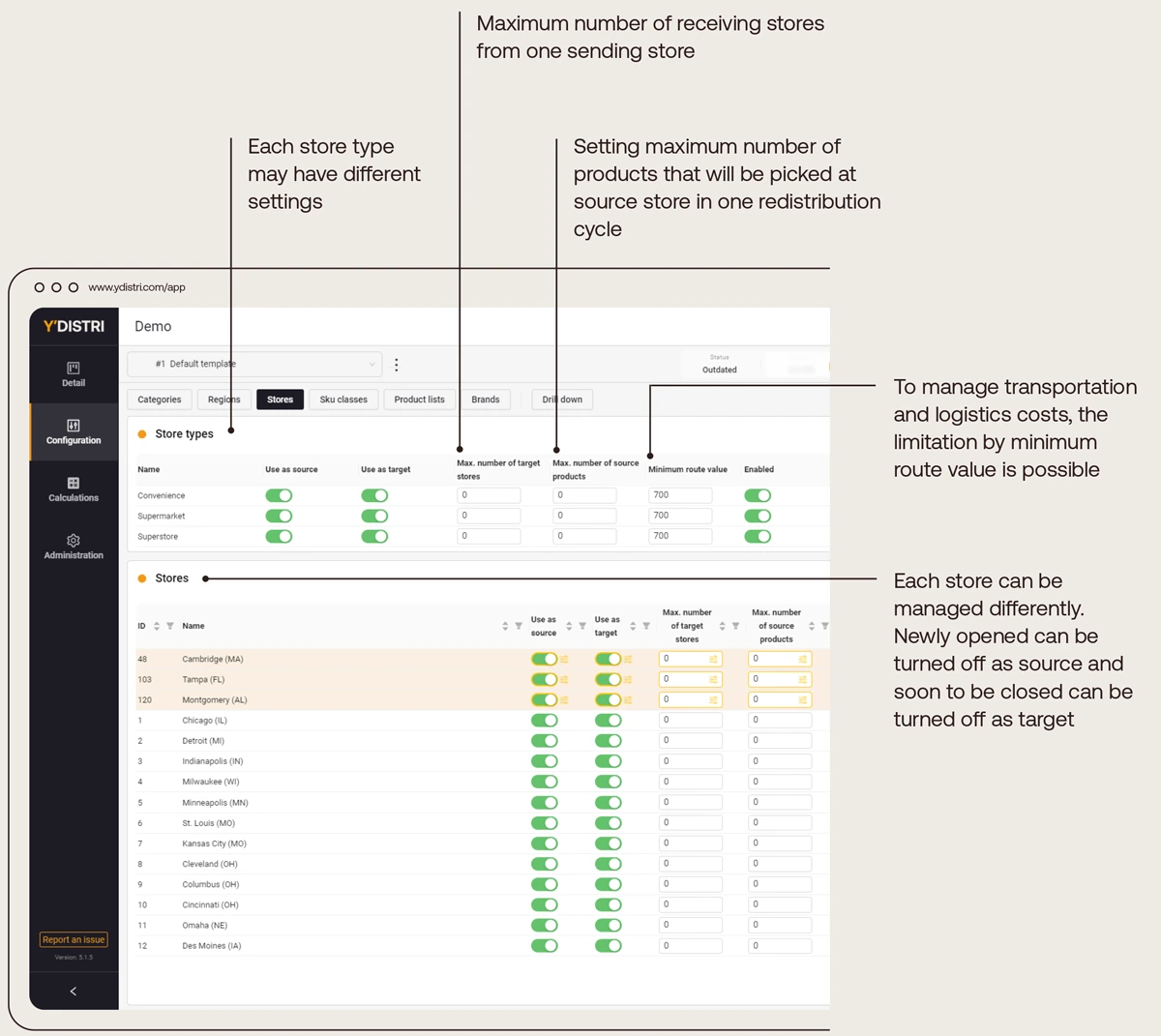

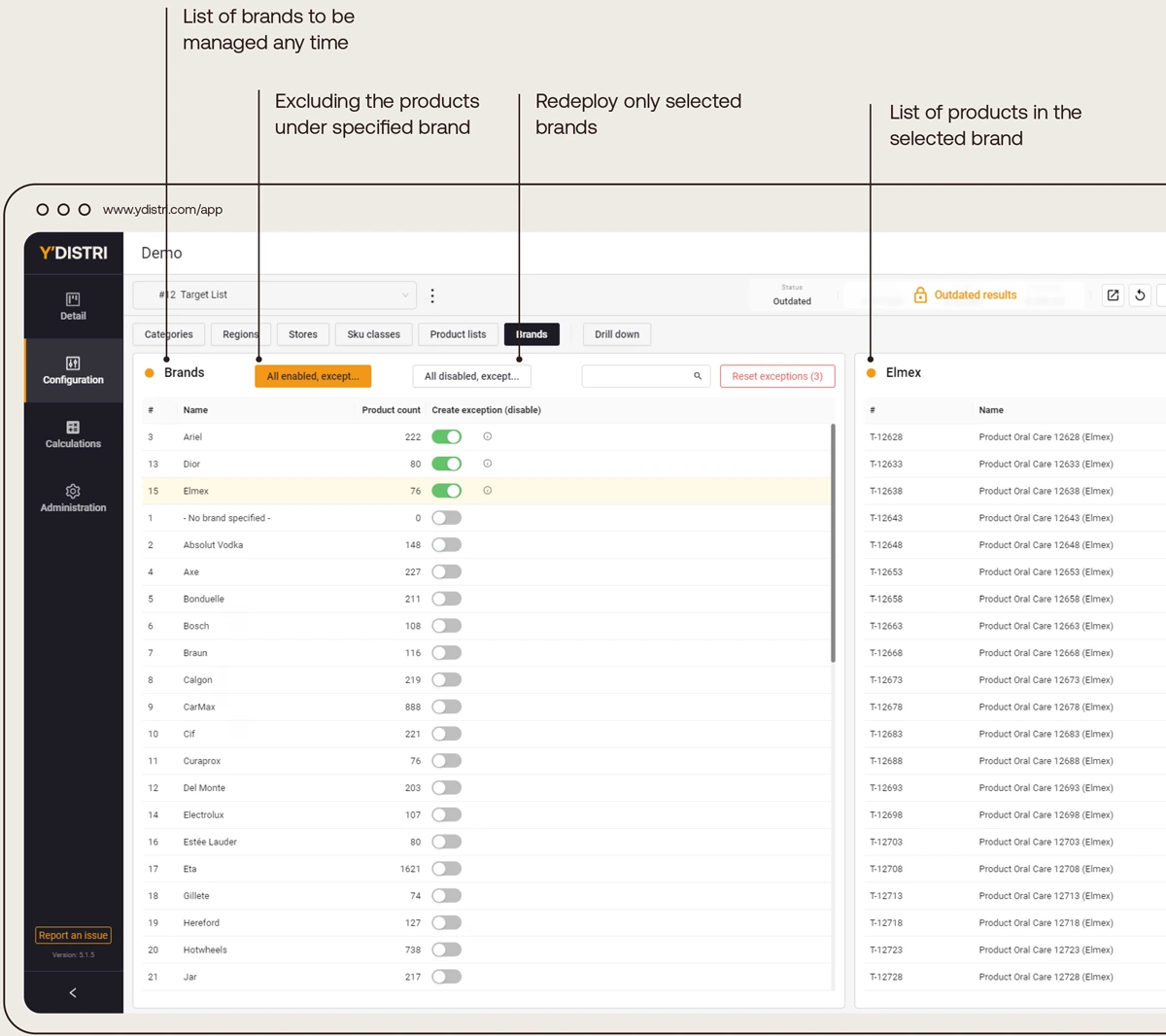

Redistribution configuration

Enable all or selected regions for redeployment. Create groups of regions among which the redeployment may take place.

- To minimize the workload and increase the effectivity a client may set limitations to route size and picking&packing workload.

- The approach may vary based on the size.

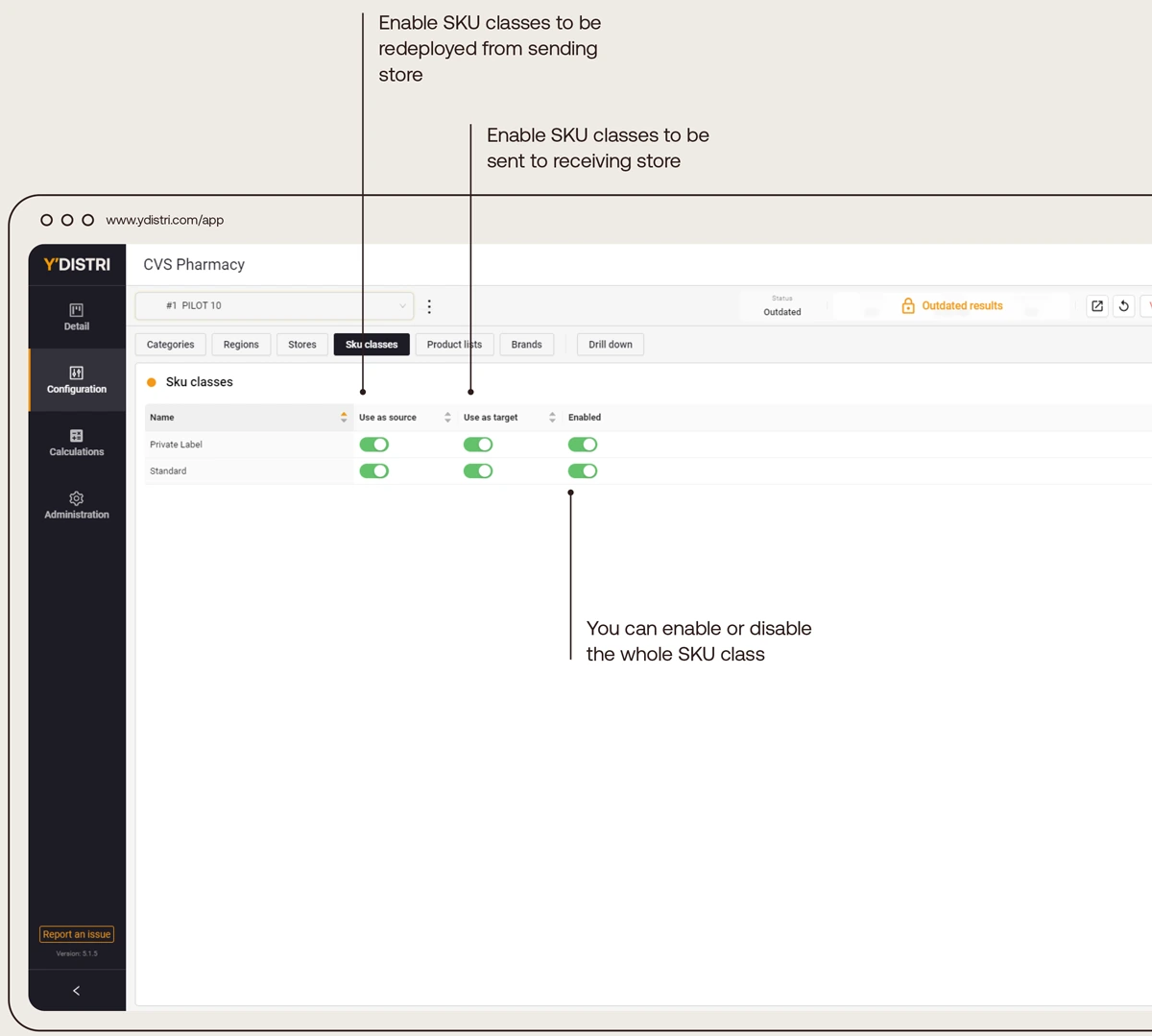

Set different approach to product classes or types.

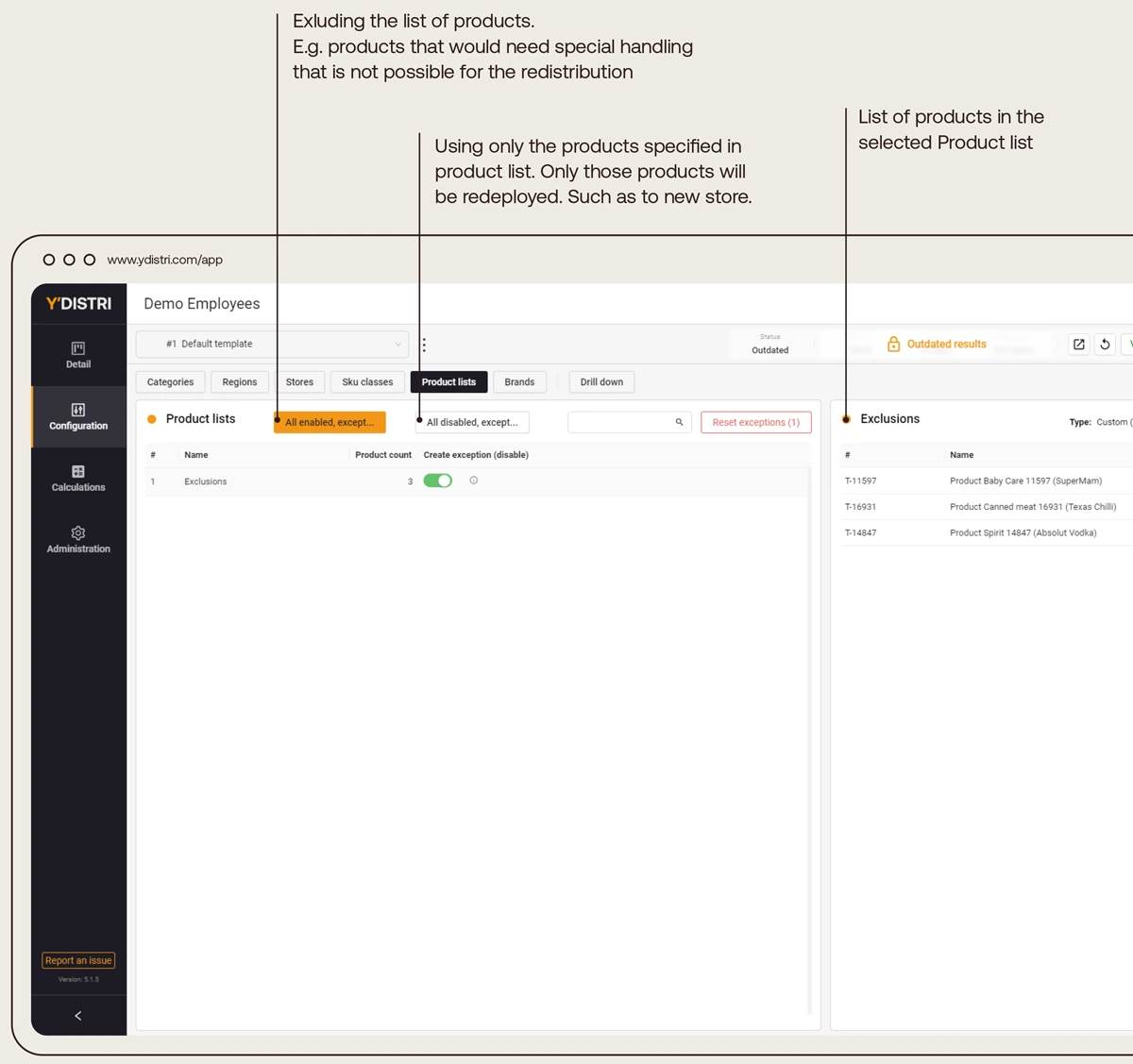

Redeploy only specified list of products or exclude it.

Redeploy only selected brands or excluded them.

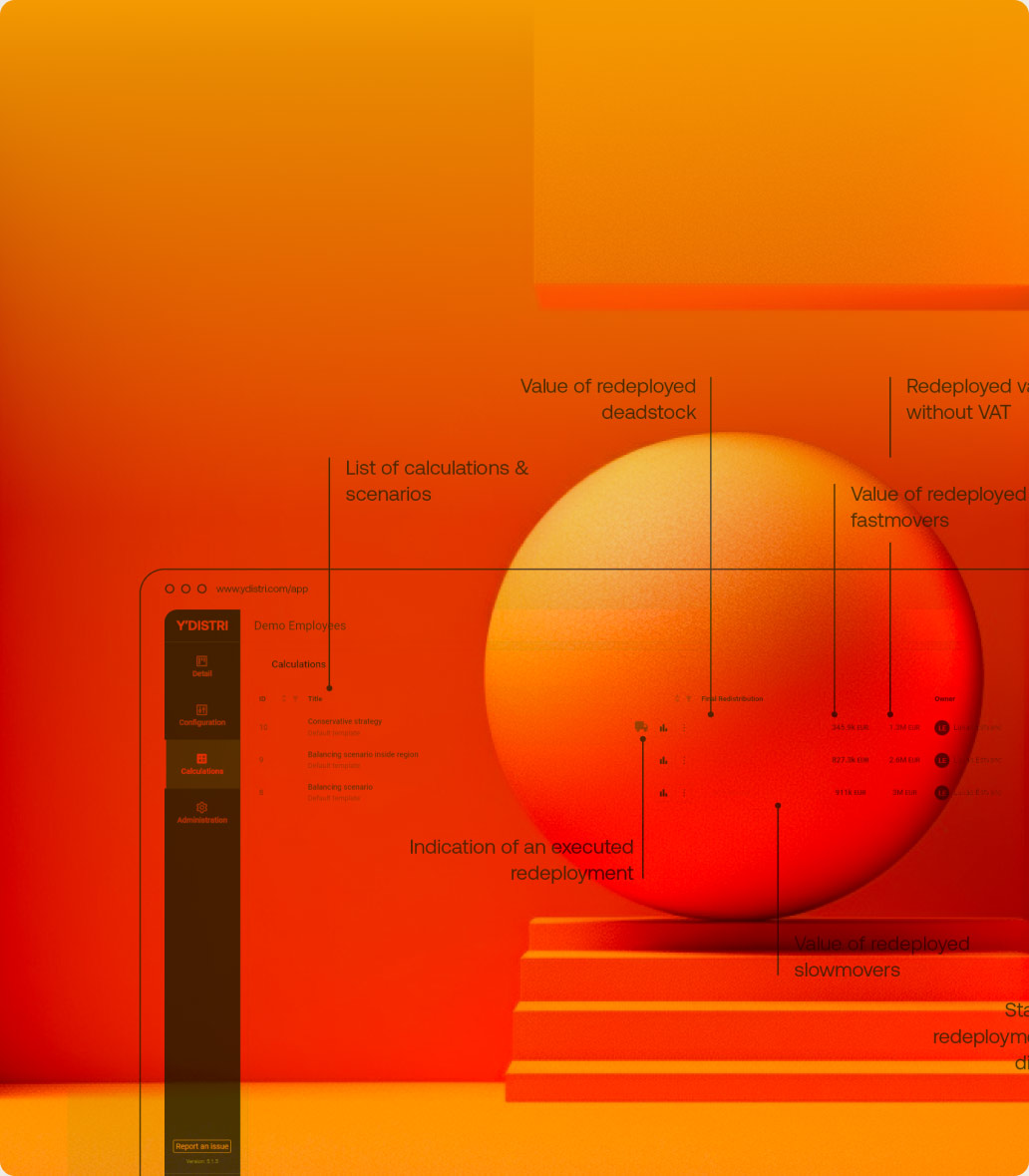

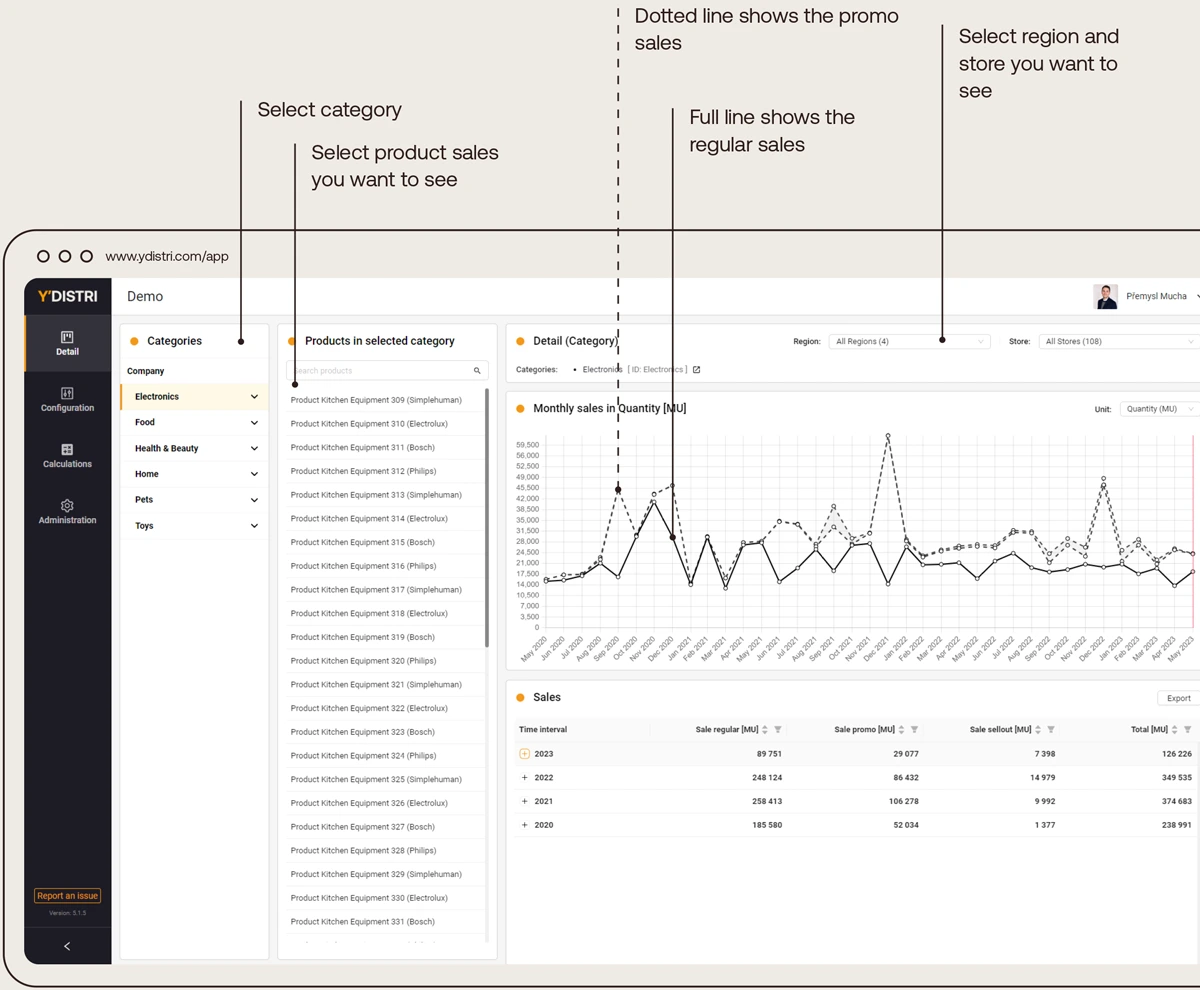

Y′08.

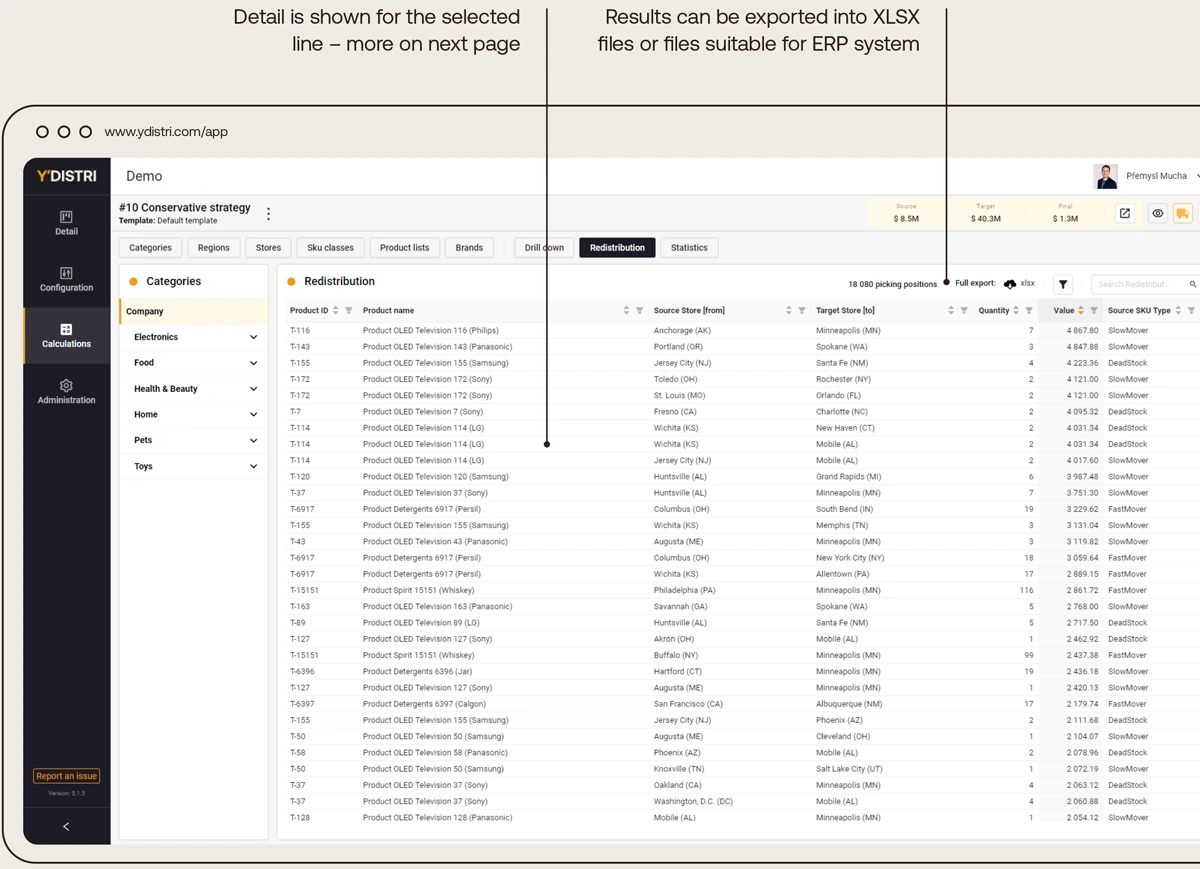

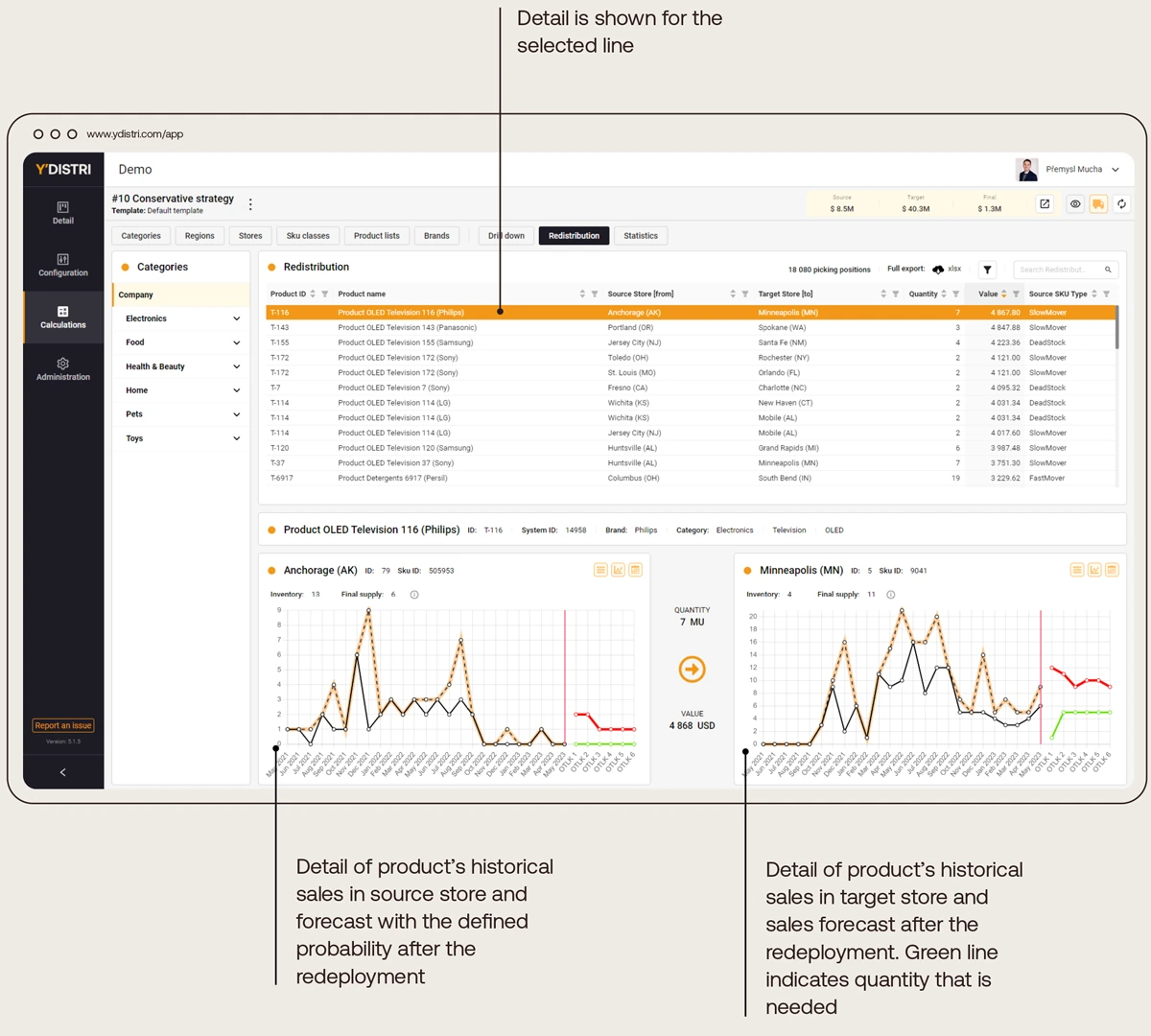

Details of the redistribution

Users can visualize and go through the detail of every single product proposed for the redeployment.

Users can visualize and go through the detail of every single product proposed for the redistribution.

Y′09.

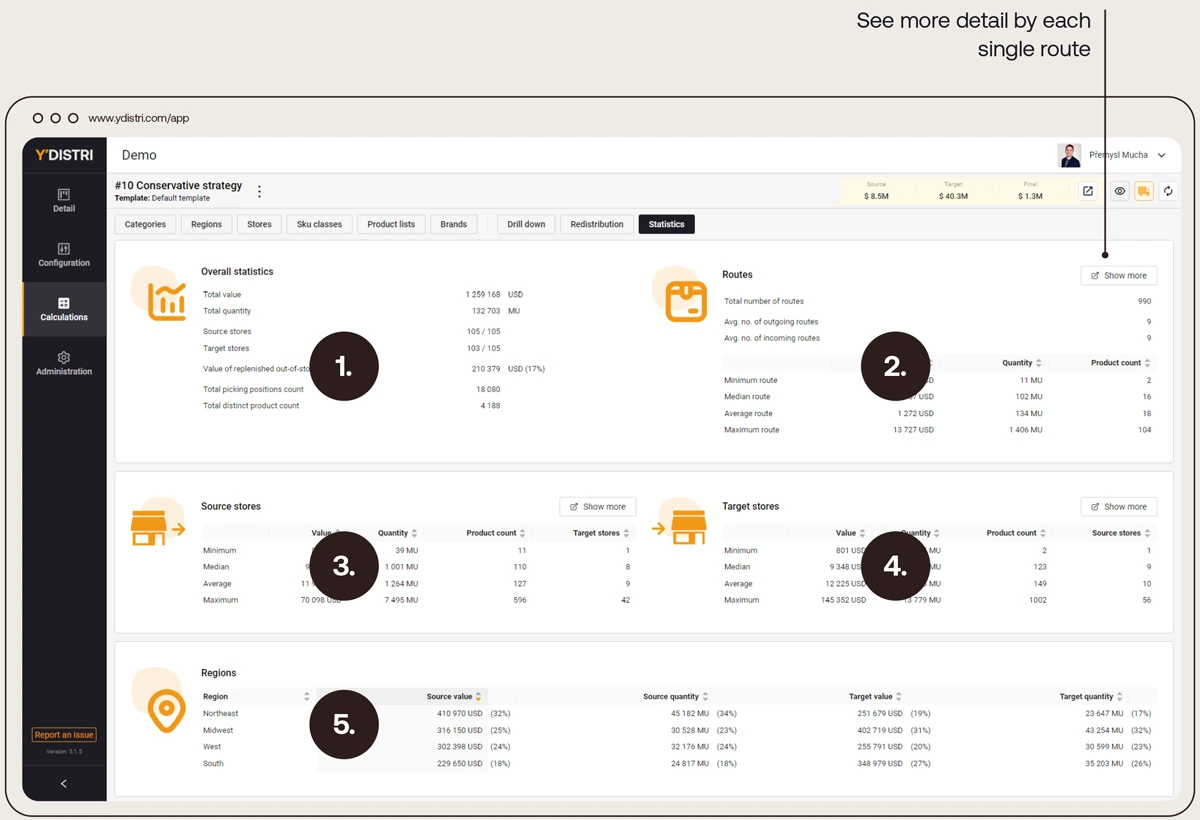

Statistics

See statistics of each calculation.

- Overall statistics: see how much was redistributed, how many stores and products were involved and the values: out-of-stocks resolved, min. layers stocked and forced products.

- Routes: overview of the values of the routes and number of the routes.

- Data of redeployed products on the sending store.

- Data of redeployed products on the receiving store.

- See redeployment split by region.

Y′10.

Drill down

See the impact on total revenue and inventory turnover in comparison to redeployed inventory.